How XW Production, an Estonian startup, is redefining utility boats for different sectors

This article was featured in Eurofish Magazine 4 2025.

A shipyard is capitalising on its founders’ flair for design and vessel building to realise a modular concept for work boats that allows them to be quickly and easily configured for different purposes.

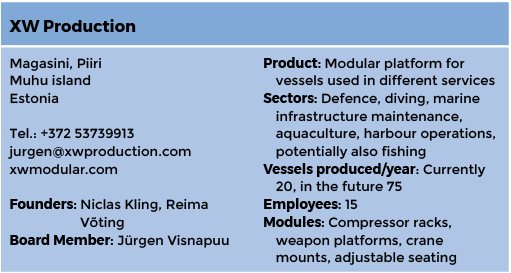

When Jürgen Visnapuu left behind a fintech venture in Manhattan and returned to Estonia, the sea became both refuge and direction. Managing Orissaare harbour on the island of Saaremaa, he encountered a small but skilled boatbuilding operation run by naval architect Niclas Kling and Reimo Võting, a shipbuilder. Their vision was as ambitious as it was technical: a modular, high-performance utility boat that could be configured like a toolkit. Out of that meeting, XW Production was born.

From maritime defence to a wide range of applications

XW Production is now an emerging player in the specialised boatbuilding market, with a concept built around flexibility, resilience, and high-spec -engineering. The company builds aluminium-hull vessels with fully modular interiors, originally conceived for maritime defence, but now catching attention from a much broader set of customers. The company is rooted in Estonia’s long tradition of shipbuilding, particularly on the islands of Saaremaa and Muhu, where skilled welders are more easily found than on the mainland. Mr Võting’s shipbuilding background includes stints with two of Estonia’s leading yards. Mr Kling, a Swedish naval architect with a coast guard background, brought in the design and technical rigour. Mr -Visnapuu added the missing link—business development and sales.

A version of XW Production’s platform being put through its paces.

Tests by the navy demonstrated the vessel’s robust construction.

XW’s flagship product is a rigid hull inflatable boat (RHIB), 7.5 metres long, capable of reaching speeds over 50 knots with a 300 horsepower Mercury engine. While that speed is impressive, what makes the boat different is how it is constructed. Everything from the console and jockey seats to cargo modules and crane mounts can be removed, repositioned, or replaced. The core idea is platform-first: the boat is built to accept a wide variety of mission-specific modules, which can be swapped quickly without tools or technical training. The military was the first serious audience to take note. Through Estonia’s Defence Industry Association, XW Production initiated a series of demo drives with navy units and special forces. One group ran the boat at full speed through harsh seas, trying to push the limits of the hull and its inflatable pontoons. After rigorous testing and inspection, they found nothing broken. This performance, combined with practical features such as rapid tube replacement (the air tubes are not glued but slide on and off), earned the attention of Estonia’s armed forces. The boat was subsequently rented for a major defence exercise and is scheduled for further military trials.

Careful design and robust construction

What stands out is how the boat’s construction aligns with operational needs. The pontoons are designed with five separate air chambers, and even if all are compromised, the boat’s buoyancy will keep it afloat. It is equipped with a network of small internal airbags that ensure stability even if the hull is breached by gunfire. The aluminium hull is robust, with welds left exposed intentionally—professional visitors to boat shows have praised their precision and quality. The modularity is not just a design flourish. Modules include compressor racks for pneumatic tools, crane mounts, adjustable seating, and machine-gun platforms. Even the main console, typically a fixed structure in most boats, can be moved or entirely removed. XW Production uses a German fastener system, similar to those in commercial aviation, and the deck railings are reinforced to support high-torque loads from towers or equipment.

The company’s boats have now been tested or used by search and rescue teams, technical diving units, and marine infrastructure firms. The Estonian navy’s mine-diving team has provided written feedback, helping XW develop a second generation of modules tailored to their needs. These include open-deck configurations, special storage for diving gear, and a mobile air compressor for underwater tools. XW is also working with TalTech, Estonia’s leading technical -university, on integrating autonomous navigation systems into its vessels. Using TalTech’s “AI Captain” platform, the goal is to offer unmanned capabilities for search, survey, or patrol missions. The vessel’s existing electronics system makes this integration relatively straightforward. Beyond defence, XW sees commercial potential in industries like harbour operations, aquaculture, and wind farm support. Mr Visnapuu, through his harbour management experience, says how large ports often require multiple vessels for different tasks—towing, patrolling, oil spill response, passenger transfer, or cargo handling. A modular platform could consolidate these into a single vessel reconfigurable for each role. Conversations are underway with Tallinn Port, Saare Wind Energy, and other state-owned infrastructure operators. The boats have already been rented for undersea cable-laying projects and are viewed as potential assets for the growing offshore wind and fish farming sectors. In particular, a Canadian seafood processor has shown interest in adapting XW’s vessels for autonomous use in aquaculture—sending out unmanned boats to feed or monitor fish stocks. Visnapuu is also in discussions with commercial fishers to understand the precise module configurations that could support their work.

Investments in capacity to increase output almost 4-fold

While production today is limited—XW can currently build around 20 boats a year—the team is working to scale up. Plans are in place for a new factory near the main harbour in Muhu. With €1.5 million in investment, the facility would include cutting and bending machines, cranes, and robot welders, increasing output to around 75 boats a year. For now, the core team remains lean. It includes the three founders, two sales consultants, and around ten people involved in production, design, and welding. Design and digital architecture are handled from the Swedish side, while the Estonian team leads manufacturing. XW is also becoming a Mercury engine dealer, providing better integration and support for -clients. XW Production’s pricing reflects its ambitions. A typical 7.5 to 9-metre boat, equipped with modular features, ranges from €250,000 to €300,000, depending on customisations. These are not pleasure boats—they are working platforms with real-world testing behind them. The business model also includes subcontracting. XW builds hulls for a well-known Swedish fishing brand, although this work is kept discreet to respect client confidentiality. This partnership has provided insight into performance optimisation and advanced marine design.

The vessel has earned compliments from industry professionals at events such as boot Düsseldorf,

an important show for the boat industry.

In materials and methods, the company is careful. Aluminium sheets are mostly sourced from Italy. Laser and waterjet cutting is done in Tallinn for now, but the planned factory will bring all these processes in-house. The emphasis remains on hand-crafted welding, especially in tight corners and complex sections, which machines cannot easily reach. Although much of XW’s innovation sits in tangible engineering, it is also part of a wider conversation about the future of maritime infrastructure. Defence clients are now asking for diesel outboards that meet strict biofuel standards. The industry is not yet ready for battery-electric propulsion at scale, due to the weight and cost of current battery technologies. Yet, Mr Visnapuu is watching this space closely, recognising that geopolitical and commercial pressures could accelerate shifts toward sustainable propulsion. For a company that only built its first demonstrator in 2023, XW Production has come far. Its prototype vessel, initially self-funded and built without a client in mind, has turned into a showcase for Estonia’s small but capable boatbuilding sector. The boat has travelled to expos like boot Düsseldorf and drawn praise from international professionals.

Flexibility and customisation are among the unique selling points

The idea behind the company—one boat, many roles—is deceptively simple. But the execution demands engineering excellence and an understanding of what different users need from their maritime platforms. Whether for a diver needing a compressor and clean deck layout, a port needing a tow vessel on Monday and a cargo shuttle on Tuesday, or a military unit needing a reconfigurable patrol boat, XW aims to provide a single solution. It remains to be seen how far the company can scale up, and how quickly. But its modular, mission-focused vision for utility vessels positions it well in a market that increasingly values adaptability and resilience over volume and standardisation. In that space, XW Production is not just building boats—it is building a new concept.